APPLICATIONS

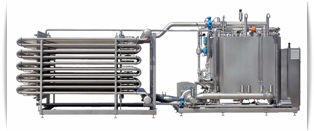

The B&P UF 200 wine

ultrafiltration system has been designed for use with food

processing technology. The UF 200 is mainly used for filtering

juices such as apple, pear, berry and stone fruit juices, as well

as fruit wines.

OPERATION PRINCIPLE

The UF 200 is a patented and fully

automatic cross-flow wine filtration system with certificate of

innovation issued by the European Certification Centre. The tank in

the circulation unit consists of 3 chambers: two chambers are used

as a batch tank, while the third chamber is used for the finished

product (permeate).

A feed pump is used to pump the raw

wine from the raw wine tanks into the batch chambers. A

re-circulating pump pumps the raw juice (retentate) at a high rate

through the modules. In this process, a thin and homogenous coat is

formed on the membrane surface. A portion of the fluid penetrates

the membranes and is pumped as the finished product (permeate) into

the permeate chamber. During the sequential double batch process

(SDV), the retentate is condensed automatically at cyclic intervals

in the batch tanks until it reaches a maximum concentration. As

soon as the maximum concentration of solids is reached, the

retentate can undergo diafiltration in order to maximize the

product yield.

All filtration processes are

managed by a program developed by B&P and can be conveniently

controlled via a 17” touch panel.

ADVANTAGES

• Maximum productivity

and excellent juice quality

• Modular structure,

high efficiency in a small space

• Fully automatic

control system with visualization technology

• Convenient

maintenance and low susceptibility to faults

• Automatic cleaning

system

TECHNICAL DATA

|

Efficiency

|

10 m3/h - 40 m3/h

|

|

Membrane Modules

|

PCI A 19 PVDF, type FPA 10/20/45

|

|

Module Length

|

3.66 m (12 feet) / 3.05 m (10 feet)

|

|

Number of Membranes Per Module

|

19

|

|

Filtration Surface

|

100 – 300 m2

|

|

Temperature Range

|

10-55 °C

|

|

pH Range

|

1.5 – 10.5

|

|

Maximum Operating Pressure

|

7 bar

|

|

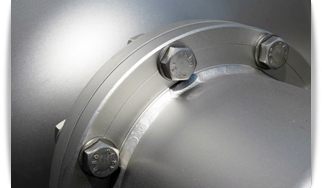

Materials

|

All elements in contact with the product: stainless steel AISI

316/304, frame support: stainless steel AISI 316/304 Seals EPDM

(FDA)

|

SCOPE OF DELIVERY

Pump and vessel unit with control

cabinet mounted on a frame, filter module unit, fully automatic

control system Siemens SP7 with 17” touch panel

OPTIONS

• 20 m3

water vessel with automatic water heating system

• 20 m3

settling vessel

• 20 m3

chemical and production leftover vessel