OPERATION

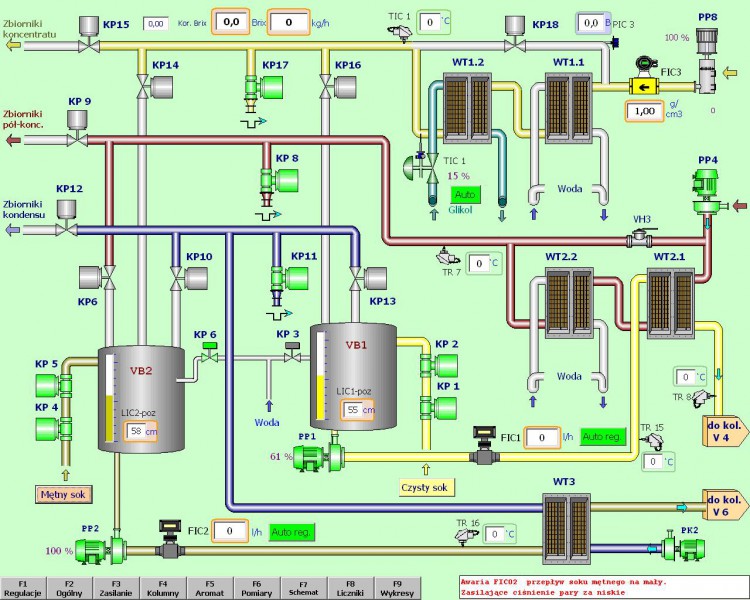

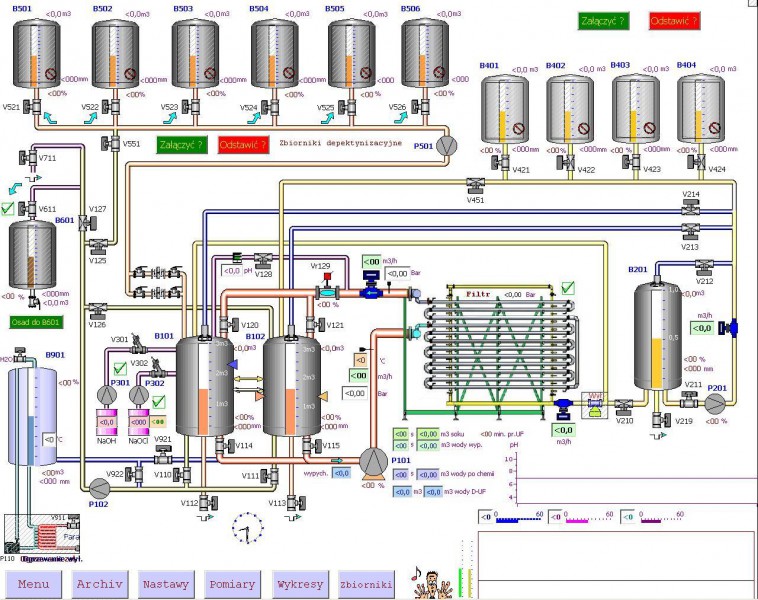

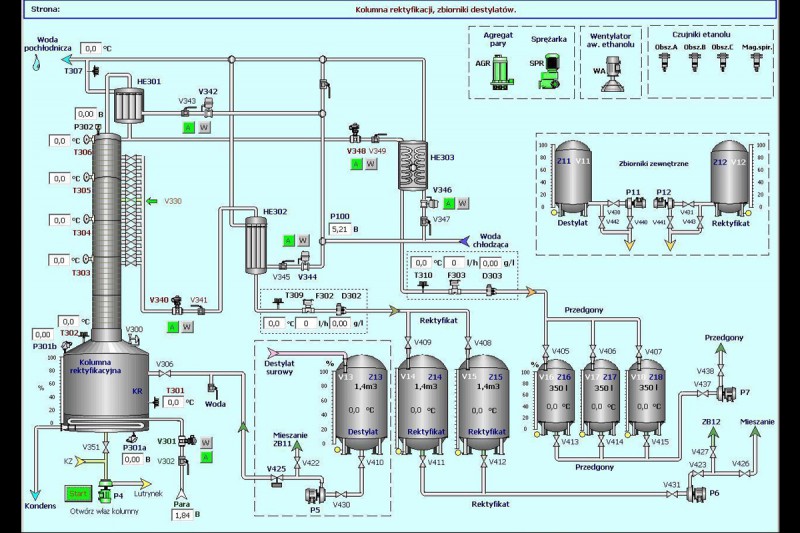

Visualization is the graphic

representation of models of technological or actual processes

displayed on a computer screen. Visualization systems allow

human-computer interaction, and down to this the user can influence

the process which is being monitored.

The application of visualization

and production process control allows continuous improvement to the

process and cost reductions. Reports from an industrial database

are helpful in detecting the bottlenecks on a production line

resulting from recurrent failures or poor organization of component

supply. Visualization systems enable continuous information

transfer from the detectors installed on the production lines or

technological installations concerning: temperature, flow, pressure

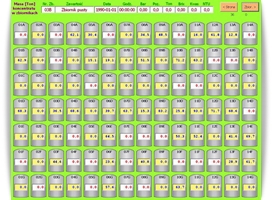

etc. The software can record readings, present current and

historical charts as well as process reports, failure alerts, and,

last but not least, present process visualization in the form of a

clear synoptic diagram with a legend and parameters displayed on

the computer screen. Visualization systems provide the possibility

of distributed process control from several operator stations. An

additional computer installed in the office of the CTO can give a

full view of plant operation.

A graphical visualization consists

of a diagram which illustrates the flow of data in a production

process. After the data for a specific technological process have

been defined, it is possible to view the status of the production

stage of a particular product. Individual production stages are

depicted as icons.

Integrating individual devices into

a network allows operational activities to be minimized and to

enhance the effectiveness of individual devices, which leads to

elimination of downtime and failures.

We also offer a system of online

production process monitoring for the whole production line.

Online access to the system also ensures remote diagnostics of the

system and monitoring. Visualization can be installed using

ordinary PCs, touchpads or panels with displays of various

dimensions.

All control systems and

visualization software are devised and programmed in our own

Software Department, which makes us independent from outside

companies and enables us to cater for the client’s needs as well as

implement any necessary changes. Upon the client’s request backup

and a hotline can be installed (e.g. in compliance with HACCP). SPS

is the core of each automation system. It is a junction for all

information about the process or a machine. The effectiveness of a

device is directly linked to the effectiveness of the SPS and

software.

OPTIONS

To ensure the convenience of device

operation we offer a wide range of operation panels.

Push Button Panel

Micro Panel

Touch Panel

Multi Panel