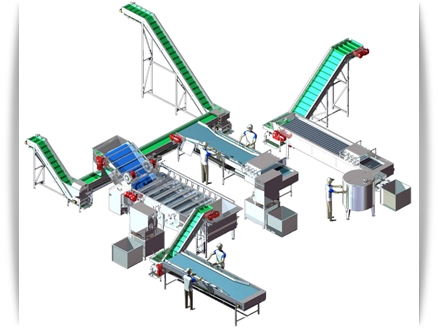

APPLICATIONS

The

devices are intended for transporting bulk and lump materials as

well as individual loads. They are used in food, construction,

transport, logistics and other industries. Belt conveyors can work

as stand-alone units or as a part of a process line.

DESIGN

•

Support frame

• Drive shaft with drive

unit

• Rollers, shoes or table for

guiding the belt

• Charging hopper

• Discharge hopper

• Belt made of flexible PVC,

PU

• Belt made of hard plastic (PP, PE,

POM)

• Drive wheels for mobile

structures

VARIANTS

Belt

conveyors can be flat, horizontal or inclined (rising or falling)

at a specific angle. Depending on the application and customer

requirements, B&P Engineering manufactures one-way or two-way

conveyors. In a one-way conveyor, the use of one drive shaft and

one driven shaft makes the belt move in one direction only. In a

two-way conveyor, two driven tension shafts and one drive shaft are

used. This makes the belt move in both directions. Belts can be

guided on shoes, rollers or directly on a table. When required by

the customer, a mesh can be installed in place of the belt. This

solution is ideal for machines intended for work in extremely low

(e.g. cooling rooms) or extremely high (e.g. ovens) temperatures.

B&P Engineering‘s conveyors for the food industry are made of

acid-resistant and plastic materials approved for contact with

food. Non-alloy steel structures are protected with an

anti-corrosive coat.

Due to the well-designed welded

structure made of steel pipes and sections and the high quality of

construction, all elements are easy to wash and auxiliary materials

have no contact with the transported product.

TECHNICAL

DATA

Belt

width : 400, 500, 650, 800, 1000, 1200 mm

Blade height (inclined system) : 50,

70, 100, 120 mm

Conveyer length : as required by the

customer

Drive motor power : Up to 7.0

kW

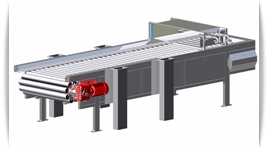

APPLICATIONS

Roller tables are used for transporting

bulk and lump materials as well as individual loads. They are used

in food, construction, transport, logistics and other industries.

Belt conveyors can work as stand-alone units or as a part of a

process line.

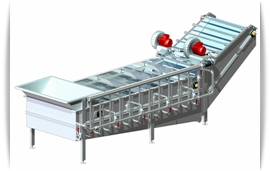

PRINCIPLE OF

OPERATION

B&P Engineering manufactures roller

conveyors according to individual customer needs and requirements.

The most commonly used transport units are:

• Drive roller tables

• Gravitational roller tables

Drive roller tables are used for sorting, separating dirt and

washing the raw material. They transport the raw material to the

next stage of the production line. This solution is used in the

food industry for washing fruit, e.g. apples.

Gravitational roller tables are the most frequently used types of

conveyors. This device is used in all industries for transporting

packaging, pallets, box-pallets, containers and other materials.

Its simple structure, consisting of a support frame and rollers,

transports or buffers the material using gravity.

COMPONENTS

OF A DRIVE ROLLER TABLE

• Rust-proof chain and rollers with arc

bearing

• Support structure

• Raceway

• Drive shaft

• Driven tension

shaft

• Drain tub with sprinklers

washing dirt off the walls

• Option – pressure

washer

• Option – double chain

wheel