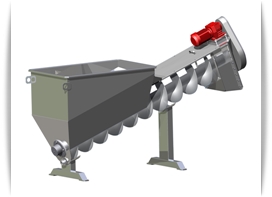

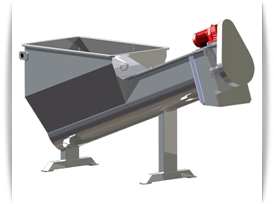

APPLICATIONS

For horizontal, inclined or

vertical (elevator) transport of bulk and fine material as well as

medium-grained and fine-grained dry and damp materials, such as

fruit, vegetables, grain and more. The device can be used as a

feeder, receiver or dosage unit.

Two

types are available:

• Closed pipe-type screw

conveyor

• U-type trough screw

conveyor

DESIGN &

PRINCIPLE OF OPERATION

The

U-type trough screw conveyor is open at the top. It comes in two

variants: with or without a cover. The U-type trough screw

conveyors also include discharge baskets fitted with an extended

charge and a screw in the bottom section. The U-type trough screw

conveyors can be fitted with a heating or cooling

jacket.

Screw conveyors can be installed on

a support structure permanently attached to the ground or be

equipped with casters for transport. The class of material the

machine is made of depends on its intended purpose. For the food

industry, the machine is made of acid-resistant material and

plastic materials approved for contact with food. Non-alloy steel

elements are covered with an anti-corrosive coat.

The closed pipe-type screw conveyor

is a pipe with a shaft inside with welded screw blades and passive

bearing. The screw’s blades have different pitch, depending on the

type of the transported raw material and the planned capacity. This

type of conveyor is closed, which means that the screw cannot be

accessed directly. Thanks to the closed structure, the transported

raw material does not spill outside the machine during

transport.

The machine can be equipped with a

pull screw. In this version, the drive unit is located in the

direction of the raw material feeding. Some screw conveyors are

equipped with push screws with gear motor installed on the feeding

side. The screw conveyor is fitted with an initial or end bearing.

Depending on the type of transported raw material, slide or bearing

rests are installed. When required by the customer, the screw

conveyor can be fitted with a washing system in the spindle. This

enables washing the conveyer from the inside, eliminating the need

to dismantle it.

TECHNICAL

DATA

Working screw diameter : 200, 250, 300, 350,

400, 500

Screw type : clockwise and

anti-clockwise turning,

Screw rotary speed : 40-112

rpm

Screw length : 1; 2; 2,5;

3m

Working trough length : as required

by the customer

Drive motor power : 0.75-18.5

kW

Capacity : up to 50

m3/h

Total length : as required by the

customer

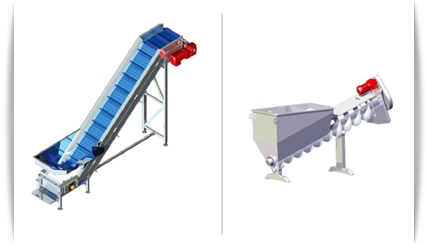

APPLICATIONS

The

devices are intended for transporting bulk and lump materials as

well as individual loads. They are used in food, construction,

transport, logistics and other industries. Belt conveyors can work

as stand-alone units or as a part of a process line.

DESIGN

•

Support frame

• Drive shaft with drive

unit

• Rollers, shoes or table for

guiding the belt

• Charging hopper

• Discharge hopper

• Belt made of flexible PVC,

PU

• Belt made of hard plastic (PP, PE,

POM)

• Drive wheels for mobile

structures

VARIANTS

Belt

conveyors can be flat, horizontal or inclined (rising or falling)

at a specific angle. Depending on the application and customer

requirements, B&P Engineering manufactures one-way or two-way

conveyors. In a one-way conveyor, the use of one drive shaft and

one driven shaft makes the belt move in one direction only. In a

two-way conveyor, two driven tension shafts and one drive shaft are

used. This makes the belt move in both directions. Belts can be

guided on shoes, rollers or directly on a table. When required by

the customer, a mesh can be installed in place of the belt. This

solution is ideal for machines intended for work in extremely low

(e.g. cooling rooms) or extremely high (e.g. ovens) temperatures.

B&P Engineering‘s conveyors for the food industry are made of

acid-resistant and plastic materials approved for contact with

food. Non-alloy steel structures are protected with an

anti-corrosive coat.

Due to the well-designed welded

structure made of steel pipes and sections and the high quality of

construction, all elements are easy to wash and auxiliary materials

have no contact with the transported product.

TECHNICAL

DATA

Belt

width : 400, 500, 650, 800, 1000, 1200 mm

Blade height (inclined system) : 50,

70, 100, 120 mm

Conveyer length : as required by the

customer

Drive motor power : Up to 7.0

kW

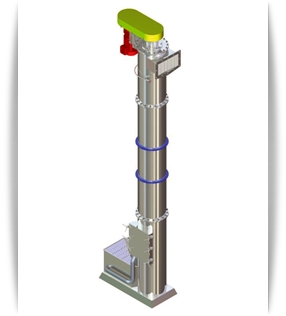

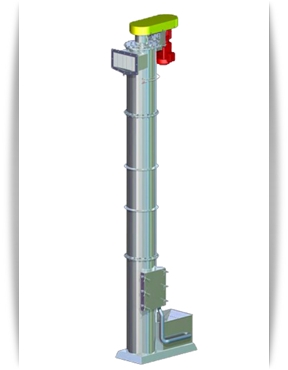

APPLICATIONS

The

device is used for vertical transport of fine, loose, powdered,

medium-grained and fine-grained, dry and damp materials, i.e.

fruits, vegetables, grains and others. It can be used as a feeder,

receiver or dispenser.

PRINCIPLE OF

OPERATION

The

elevator consists of a tube, including interior shaft with

adjustable screw blades and passive bearing. Screw blades vary

depending on the type of transported material and the planned

capacity. This tray is closed, which means that there is no direct

access to the screw. Thanks to the closed structure, there are no

problems with dusting and the products do not spill outside the

machine during transport. The device can be equipped with a pull

screw. In this version, the drive unit is located in the direction

of the raw material feeding. Some screw feeders are equipped with

push screws with a gear motor installed on the feeding side. The

screw feeder is equipped with an initial or end bearing. Depending

on the type of transported raw material, slide or bearing rests are

installed. When required by the customer, the screw feeder can be

fitted with a washing system in the spindle. This enables washing

the conveyor from the inside, eliminating the need to dismantle

it.

TECHNICAL DATA

-

working screw diameter : 200,

250, 300, 350, 400, 500

-

type of screw : clockwise,

anti-clockwise

-

Screw rotation speed : 40 - 112

rpm

-

screw length : 1, 2, 2.5,

3m

-

working trough length : according

to the customer's needs

-

motor power : 0.75 - 18.5

kW

-

capacity : up

to 50m3/h

-

total length : to be arranged