HYDRAULIC (FLUME) DISCHARGE /

UNLOADING

APPLICATIONS

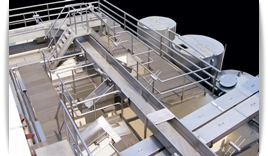

The

wet unloading system is used for unloading and transport of raw

materials to the preproduction storage. A series of devices and

installations transport the materials from the unloading point to

the storage silos via navigable channels.

OPERATION

The

system for manual setting of the raw materials and the water sorter

allows a free choice of silo to which the fruits are to be

delivered and enabling the comprehensive and even filling of the

chambers. The system enables the simultaneous separation of water

from the raw material. The water separated from the hydro transport

system is passed to the drum catcher to remove

impurities. This solution is a closed cycle system the water

transport of raw materials that will continue for a specified

period of time.

SCOPE OF

DELIVERY

Cannon for unloading fruits from

vehicles - mounted on the structure at a

height of about 4 m above the unloading ramp, controlled

automatically from the operator's room, enables flushing

(unloading) of raw material from the vehicle using a water stream,

produced by a centrifugal pump that is located in the circulating

water channel of the hydro transport system. The raw material is

flushed into a chute connected to a bucket conveyor

container.

Operator's room for operating the

cannon and the system for flushing raw materials

- is equipped with the electro-pneumatic panel

with the possibility of switching and controlling equipment for

unloading and transporting apples.

Bucket conveyor for transport of

raw material from the unloading chute to the navigable channel

- designed as a belt conveyor with openwork

buckets attached to the belt. Openwork buckets are used for

vertical transport of raw material and separating the water from

it. The belt is driven by a motor reducer with the option to adjust

the belt speed (capacity regulation) using a frequency

inverter.

Navigable channel with sorters

- made of 1.4301 chromium-nickel steel, used

to transport apples from the bucket conveyor to the silo, equipped

with a system of vents that direct the raw material to particular

silos. The self-closing flap construction ensures its sealing in

the event of closure. Each sorter is equipped with a grate that

drains the water back to the hydro transport system. The dried

apples fall into the silo.

Buffer tank for circulating water

- A tank of a capacity to match the needs of

the installation, used to buffer the supply of water for the hydro

transport system. Material: 1.4301

Arched filters - Slotted arched

filters are used for the initial cleaning of the circulating water

in the hydro transport system. Each filter is responsible for one

water cycle.

Material

: 1.4301

Capacity

: dependent on the needs of the

installation

Pneumatic control panel

- The panel is located in the operator's room,

and is equipped with actuators for the control of equipment in the

unloading and hydro transport lines. The panel is made of 1.4301

chromium-nickel steel and has an appropriate level of IP protection

against environmental influences.

ADVANTAGES

-

Simple operation

- High performance

- Reliability

- Low maintenance costs