APPLICATIONS

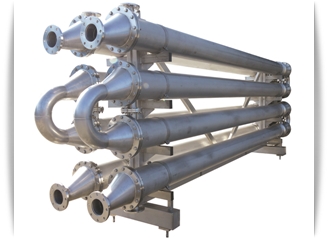

The

B&P tube heat exchanger is particularly suited to the thermal

treatment of products with a high viscosity range as well as

products containing solids, pulps or fibrous products.

Our

systems are designed to be installed as part of heating, cooling

and aseptic systems and are used in the fruit juice, milk and

brewing industries.

OPERATION

PRINCIPLE

The

B&P tube heat exchanger is a tube-in-tube system. The operating

medium – hot water – is prepared in a hot water pre-heater using

steam. A circulating pump is used to pump it into the external tube

of the heat exchanger. The product flows in the opposite direction

through the internal tube of the heat exchanger module and is

heated up to the set temperature by the hot water. Once the water

has dissipated its heat, it flows back to the circulating pump to

be reheated.

Tailored to suit every efficiency range and the

product’s physical properties, our models are sure to include the

optimal solution for your specific needs. We also offer individual

solutions for specific applications.

ADVANTAGES

• Gentle heating of the product

ensured by short retention time

• High efficiency

• Low space requirements

• Convenient maintenance

TECHNICAL

DATA

|

Efficiency

|

3 to 60 t/h

|

|

Heating system

|

Steam – water

|

|

(Δ t) max. temperature

increase

|

Δ 25-50°C

|

|

Circulating pump

|

3-7 kW

|

|

Steam pressure

|

Up to 4 bar

|

|

Air pressure

|

6-8 bar

|

|

Steam consumption

|

Approx. 2 t/h (apple mash: 30

t/h, Δ 20°C, at 2 bar)

|

|

Dimensions (30 t/h

system)

|

Approx. 8 x 0.9 x 2.6

m

|

|

Materials

|

Stainless steel AISI 304/optional

AISI 316 L

|

SCOPE OF

DELIVERY

• Heat exchanger with double pipe

system

• Hot water station

• Hot water circulating

pump

• Piping material

• Steam control valve

• Safety valve

• Control cabinet with integrated

control system

OPTIONS

• Insulation: mineral wool,

Armaflex, insulation plates (full insulation)