APPLICATIONS

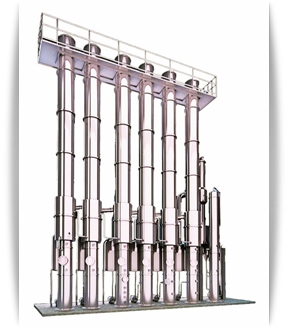

The

B&P evaporation system system has been designed for use in the

food, chemical and pharmaceutical industries. The system is used to

concentrate various types of fluids.

OPERATION

PRINCIPLE

B&P’s evaporation system system is a falling film

evaporation system with certificate of innovation issued by the

European Certification Centre. Depending on the requirements, the

system can be equipped with up to 6 sections. The product to be

concentrated is distributed on the heating pipes and a thin film is

created as it flows downwards. The heating steam is used to heat

the pipes from the outside, causing the fluid to boil and

evaporate. Fluids and vapors are separated in the lower section of

the heating element.

The concentrated fluid travels to the subsequent concentration

section, while vapors are directed to the separator and are later

used for further evaporation. The product must undergo all

evaporation stages in order to achieve the desired degree of

concentration.

Each B&P evaporation system

system is designed based on extensive consultations. Thanks to our

excellent vertical integration, we can guarantee high flexibility

and ensure that all process and customer requirements are met.

ADVANTAGES

• High efficiency

• Gentle treatment of the evaporated

product ensured by short retention time

• Convenient maintenance and low

susceptibility to faults

• Low steam consumption

• Fully automatic control system

with visualization technology

TECHNICAL

DATA

|

Evaporation efficiency

|

7,000 to 40,000 l/h

|

|

Number of sections

|

Up to 6

|

|

Heating

|

Steam

|

|

Steam consumption/water

evaporated

|

From 0.217 kg steam/kg evaporated

water

|

|

Steam pressure

|

8 bar

|

|

Power input

|

60-300 kW

|

|

Materials

|

Stainless steel AISI304/option

AISI316L

|

|

Dimensions/6-section

system

|

Approx. 14 x 3.5 x 14

m

|

SCOPE OF

DELIVERY

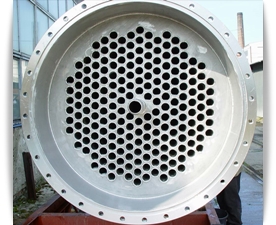

• Heating element with integrated

CIP and feed tanks

• Tangential separator

• Surface condenser

• Pipe coil pre-heater

• Plate heat exchanger

• Pumps

• Piping

• Fully automatic Siemens S7 control

system with 17” touch panel

• Maintenance scaffolding

• Process Monitoring

Section

OPTIONS

• Cooling towers

• Refrigerating machine

• Product cooling

•

Aroma station for intensifying and recovering the aroma

during the concentration and rectification process.